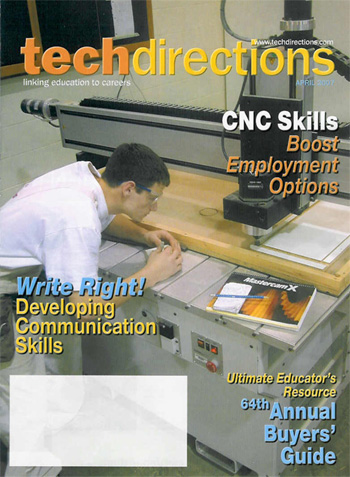

CNC Router

Educational Success Stories

Affordable Precision Educational CNC Router Affordable Precision Educational CNC RoutereMail us at technosales@technocnc.com |

| As

Seen in: techdirections, April 2007 Edition, Pages 11-13

‘CNC Skills Help Carpentry Students Snare High-Paying Jobs’ By John Panella

But technology is having a major impact on the carpentry field. Computerized and numerical control (CNC) machines now provide the ability for people with computer skills with far fewer years of carpentry experience to produce complicated parts faster and to a higher level of accuracy than the most skilled craftsmen. The Mahoning County Career and Technical Center, Canfield, OH, is riding this wave by providing a program that teaches students carpentry skills as well as how to program and operate CNC machines. Students who have completed this program can, when they graduate, produce work on the level of a skilled craftsman and so can demand substantially higher wages than other graduates. Of the school's graduates to date in the CNC program, every one has either taken or turned down jobs in the carpentry field at wages approximately twice the level of entry-level carpenters without CNC skills. The program's advisory committee has proved instrumental in initiating changes in the program's curriculum. "There are too many carpenters out there framing houses, and they are undercutting each other on price so much that it doesn't pay to keep training these kids in that area," said one advisory member. "There is a greater need for finish carpenters and custom cabinetmakers." He also stated, "CNC work in a cabinet shop, now that's where the money and opportunities are." Mahoning County Career and Technical Center offers a two-year carpentry and cabinetmaking program, which I teach, that focuses on two major areas: residential/commercial carpentry and cabinetmaking. On successful completion of both phases of the program, students can apply for apprenticeship positions in the building trades or directly enter the building trade’s field. In the residential/commercial carpentry area, we teach all aspects of residential home building and light commercial carpentry, as well as computerized drafting and estimating. In the cabinetmaking segment, we teach all phases and most types of cabinetmaking. Students learn to design, build and finish cabinets. Students build both wooden-face frame and laminate cabinets. Students can also participate in carpentry and cabinetmaking apprenticeships. Adding CNC to the Carpentry Program About five years ago, cabinet shops in our area began purchasing CNC machines in an effort to improve their productivity and quality. CNC machines automate the work of conventional power tools by using computer-generated commands to move the cutting surface with far more precision than that achievable by even the most experienced craftsman. Getting the most out of these machines requires considerably different skills than those required in the use of power tools. Rather than controlling the tool with their hands, students must learn to create a model of the part they want to make on the computer in three-dimensional space. Once they have accomplished this task, they can easily convert their model into a CNC program that will cut out the part to a high level of accuracy. In addition, the machine will build as many parts as desired without requiring any attention on the part of the operator beyond loading the raw stock and pressing the start button. The owners of several local cabinet shops expressed great difficulty with finding people who could program CNC machines. I decided to elevate the carpentry and cabinet-making program to increase its emphasis on technology in general and CNC in particular. I spoke to five local cabinet shops that were not using CNC machines and learned that they were in such dire need of skilled programmers and operators that they would purchase CNC machines for their shops if I could train students to program and operate the machines. "Most of us don't want to take time to learn about computers and are too busy to stop overseeing our shops to learn," said one shop owner of 32 years. Choosing the Right Equipment The decision of which machine to purchase was an important one. While the basic skills required to program any CNC machine are the same, there are subtle distinctions between the different machines and programming software. I wanted to prepare my students to move as rapidly as possible into high-paying jobs, so I consulted the owners of our local cabinet shops to get their ideas on which machine my students should learn to maximize their value in the workplace. The companies had researched the market prior to purchasing their machines, and most had selected Techno machines. I looked closely at the Techno machine and felt that its wide use in industry would make it an ideal learning platform. Techno machines have the right mix of features for small and medium-sized cabinetmakers. For example, they have ball screws on all three axes and closed loop servo systems. These are the type of features required to produce top-quality cabinets at a competitive price. Techno machines also equip shops to handle many jobs that are impractical to produce by hand because they would take too long, such as complicated three-dimensional contours. Yet a machine with a 4' x 8' table and all the required software costs less than $20,000. Not all students participate in the optional CNC section of the course, partly because it demands relatively high computer skills combined with reading comprehension. We teach the students to program the machine using a software package that is popular among cabinet shops. The most difficult task involves defining the geometry of the part. Students must first think through every detail of the part to fully understand its geometry. Then, they can use the software to construct the geometry on the computer, first in the form of lines, then surfaces and finally as 3D volumes. For example, I often give my students the assignment of producing a 12" deep x 8' high cabinet starting with 60" wide x 108" long Melamine board. Students begin by creating cubes to represent the walls of the cabinet. They then add dadoes to their model every 12" by subtracting volumes from the walls to produce the two sides of the cabinet. It's important to note that once students have created the program, they add it to their library so they can reuse it whenever they need it. Then, students download the program to the machine, clamp the board to the machine table, hit the start button and cut out their first cabinet. It's a very simple design, but the accuracy is better than could be achieved by the most experienced master craftsmen. And the students have done it with only a few weeks of instruction as opposed to the decades normally required to become an experienced cabinetmaker. Moving to More Advanced Projects Later in the course, my students have an opportunity to program more complicated high-end designs, such as the curved cabinets and woodwork sometimes found in expensive custom homes. Curved woodwork is very difficult to produce by hand with a router and a template. Assuming the curve of the cabinet is concave, interior parts, like the box, must have one radius while parts farther out, like the door, must have a larger radius. Students can leverage software features to program curved cabinets and other complex geometry in much less time. The cabinetmaking profession is undergoing a revolution because there is no limit to the designs that you can produce with a CNC machine. I find it quite amazing to see what our graduates can do after they get a year or two of on-the-job experience. The students that participate in this program have an easier time finding their first job and earn more money than those who do not. In the last four years, 15 students have completed this phase of the program. Most of them got job offers of $10 per hour and higher while still in school. When they graduated, all received full-time job offers from local cabinet shops. Ten former students still work in the field in this area, and most of those have seen their incomes steadily in-crease. The other five have accepted opportunities in other fields. In some cases, their CNC training helped prepare them for their current work outside the field of carpentry. For example, one of my students now uses his CNC knowledge in his pattern-maker apprenticeship in a local foundry. It's pretty obvious that CNC will play a major role in the future of cabinetmaking and other industries-and we're preparing Mahoning graduates for future success in those fields. |

Techno is celebrating over 25 years of CNC technology

expertise. Our Educational sector provides industrial quality products

at educational prices with a network of award-winning Educators. We can

provide CNC Curriculums, CNC Projects, Technical Information and

Packages for any educational classroom.

Techno is celebrating over 25 years of CNC technology

expertise. Our Educational sector provides industrial quality products

at educational prices with a network of award-winning Educators. We can

provide CNC Curriculums, CNC Projects, Technical Information and

Packages for any educational classroom. Wages

of entry-level carpenters have been driven down along with those

of many other nonprofessional occupations in recent years. If

carpenters stay in the field, they typically advance slowly over

the years until they reach the level of master craftsman, perhaps

by the time they read the age of 40.

Wages

of entry-level carpenters have been driven down along with those

of many other nonprofessional occupations in recent years. If

carpenters stay in the field, they typically advance slowly over

the years until they reach the level of master craftsman, perhaps

by the time they read the age of 40. Integrating

CNC Instruction into the Program

Integrating

CNC Instruction into the Program