CNC Router

Educational Success Stories

Affordable Precision Educational CNC Routers Affordable Precision Educational CNC RouterseMail us at technosales@technocnc.com |

|

Meeting Modern

Manufacturing Technology Face-to-Face

"We, spend $ 200, maybe a little more, for a year’s stock," he says. Therein lie some pointers for consideration. There’s also a side trip into the more exotic realm of machining from digital point measurement: finite element analysis, the stuff reverse engineering is made of. It’s all part of the end Filsinger seeks for students who matriculate through any of his magnet areas: exposure to the full design-production-marketing cycle. "Then, he says, "they’re ready to target an employer or a college with a portfolio and experience that identify them as serious players in an expanding global market." Beyond that, he understands his importance in helping his school fulfill its mission. Now in its 14th year, Suncoast Community High School was specifically established to attract a diverse student population by offering an alternative to the regular comprehensive high school. A "Magnet School of Merit" and U.S. Department of Education "Blue Ribbon School" in Riviera Beach, FL, Suncoast offers a college preparatory curriculum with a mission to end minority isolation. The school provides a challenging, innovative program to a diverse student population. Each individual is empowered to succeed in and contribute to the global society by engaging in challenging academic course work in several unique advanced-placement programs. Both the Advanced Placement Program and the International Baccalaureate Organization rank Suncoast, in the nation’s 14th largest school district, as one of the top schools in the U.S. Filsinger has designed his intermediate curriculum as a progression of applied skills grouped by the stages required to use CAD/ CAM/CNC to turn unique stock pieces into increasingly complex finished products. The variables inherent in these projects are Filsinger’s platform for teaching and/or reinforcing basic math skills-"real-life math skills the kids will definitely need for their SATs," he points out.  Relearning basic geometry factors. "Some

students studied for their Geometry I tests and promptly forgot the

basic relationships of diameter vs.radius, how to read a ruler,

parallel vs. perpendicular and even what ‘perpendicular’ means. Relearning basic geometry factors. "Some

students studied for their Geometry I tests and promptly forgot the

basic relationships of diameter vs.radius, how to read a ruler,

parallel vs. perpendicular and even what ‘perpendicular’ means.

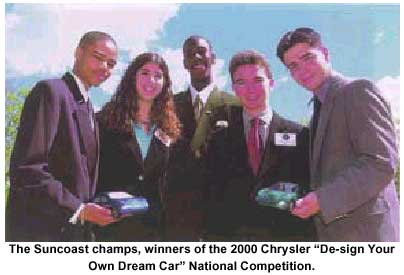

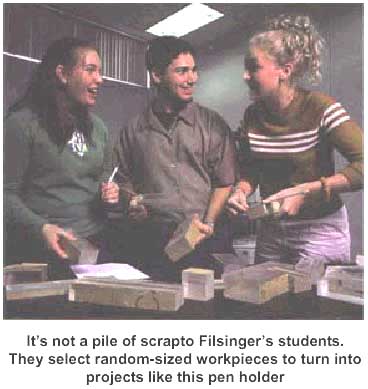

"They have forgotten because," according to Filsinger, "they weren’t shown its relevance to real life. They studied Algebra II only so they could pass the State test, and on and on. But when they must remember the material in order to complete a practical project, it sticks with them." Setting up toolpaths. Students must make tool choices based on the smallest radius they will cut."Students must create a mental relationship between the geometry they will cut and the tools they’ll use to do it. They must understand the rules about the maximum depth of any single toolpath, and they must examine their project and calculate how many toolpaths they must make given those parameters of pocket depth." Project precision = precision measurement = precision thinking. "When my students realize that, unless they’ve accurately carried out 10-based measurements, they’re, going to crash a tool into the stock, the fixturing, or the table. All of a sudden the theoretical becomes a practical concern. Many of them have never used a micrometer or calipers. To do the class work, they must add, subtract, divide, multiply; they must exercise some, rusty basics." Physics principles met or remembered. "Some kids haven’t had physics, or maybe they’ve forgotten the basics. For instance, when a student has machined a brass piece and picks it up, it’s likely to be warm."The same action with an aluminum piece would result in burned fingers-that’s practical thermodynamics. Link that to the need for different coolant flow for different metals. "It’s the same with the properties of hardness and how they affect cutting speeds. The kids learn the different cutting parameters for machining aluminum, brass, and acrylic. Their need to retain information they thought was useless is brought home in an emphatic, hands-on way." Rick Filsinger’s students have carried off six Firsts and four Seconds in the Chrysler’s Miami-regional "Build Your Dream Car" competition. In 2000, they bagged Third, Second, and First Place in the regionals plus the May 25"’ national championship. That award reflects the quality of Suncoast’s education and the caliber of students attracted to this very special secondary program. But what technology teacher doesn’t have budget worries? Filsinger insists that mining scrap industrial piles can dramatically lower materials costs and provide an additional curricular challenge. Rather than receiving a precut piece of stock or using general shop tools to cut stock to a precut size, Filsinger’s students receive his recycled, random-sized stock: very economical acrylic industrial scrap. Since the pieces are cut in random sizes, students can’t share, machining programs. They also must learn or refresh their skills on using precision measurement devices because they begin each project by measuring the stock. "Some of my colleagues use machinable, reusable wax to cut costs," says Filsinger, "but my students need examples of their work to augment their portfolios. This way, I keep my material costs to a minimum, and each student can take home each of her or his projects."  The frugal Filsinger also focuses on

keeping tooling replace-ment costs low. He requires students to

start a dry run of every project 1" above the 0,0,0. Though

each student uses toolpath verification, I want the dry run,"

he says, "because, for example, if a student fails to enter a

spindle speed while setting machining parameters, the spindle doesn’t

turn on when the program executes, the tool is forced into the work

piece, and then it usually snaps when the machine starts its run.

"A crashed dry run causes a little embarrassment, but not a

broken tool. Also, if there’s a holddown, clamp, or screw head

sticking up from their piece and they haven’t allowed for the

proper tool limits, it’s `Goodbye, tool; goodbye, budget"’ The frugal Filsinger also focuses on

keeping tooling replace-ment costs low. He requires students to

start a dry run of every project 1" above the 0,0,0. Though

each student uses toolpath verification, I want the dry run,"

he says, "because, for example, if a student fails to enter a

spindle speed while setting machining parameters, the spindle doesn’t

turn on when the program executes, the tool is forced into the work

piece, and then it usually snaps when the machine starts its run.

"A crashed dry run causes a little embarrassment, but not a

broken tool. Also, if there’s a holddown, clamp, or screw head

sticking up from their piece and they haven’t allowed for the

proper tool limits, it’s `Goodbye, tool; goodbye, budget"’

As you’d expect, beginning students in the Engineering Technology curriculum begin designing and machining in two dimensions. When they reach the intermediate stage, they begin 3D design and toolpathing, with one significant variable: Though they have predefined general project parameters, material sizes vary and other unknowns remain that they must solve for. The projects follow sequentially, in order of increased complexity. Here are three: The power of the pen: One advanced project, a penholder with base, challenges pragmatic engineering and precision toolpathing. The turned brass penholder must be freestanding putting normal pressure on the brass part won’t force it out of its acrylic base yet be able to slip in and out for ease of "shipping and customer assembly" in the real world. "I provide details on the shape of the brass penholder, the diameter of the bore, and the shape of the ball end which must fit inside the base," says Filsinger. "The brass pen holder is machined on a Light Machine PL3000, with an eight-tool turret head. I assign my students to compile at least three toolpaths and make at least one tool change in the process of machining. "Clearance, between the brass holder and the hole, machined with a pocket toolpath into the base, is 0.010". If done correctly, the pen holder will hold securely, can be adjusted in a variety of positions, and can be inserted and removed easily." Students must design and toolpath the acrylic base, selected from random sized stock, to conform to standard finish characteristics. They must use concave and convex arcs to create a swept surface around the upper edges of the base and machine it using a flowline toolpath. Then they must generate a contour toolpath to project their personalized engraving onto the surface plaque.

To complete the card holder, the kids engrave their names onto the Coons surface. To do this, they generate a flat contour toolpath of their name, save it as an *.nci file with a depth of 0.10". The *.nci is then projected onto the Coons surface. Depending on the, size and number of the letters to be created, students choose either a 1/8" or 1/16" flat end mill to perform the engraving. "The results are pretty dramatic," Filsinger asserts. "Students use random stock sizes to create the project, and they learn the value of creating text files to remind them which cutters are used to cut each toolpath. In effect, they are prototyping a product using fixed parameters on non-standardized stock sizes. "It’s a great motivator, too," Filsinger continues, "because, though the description of the process looks complex, the kids have already learned the, basic skills to begin the project. They add to their skills inventory as we work through the project together. "They’re proud when they see the beauty of the piece they’ve learned to create, and they have moved up a notch on their ‘personal marketability’ scale."

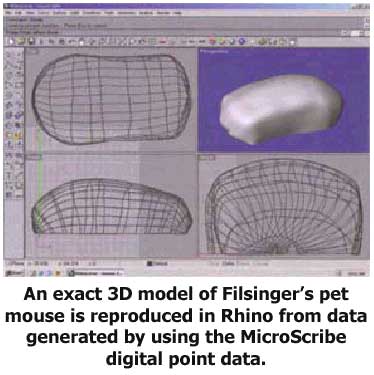

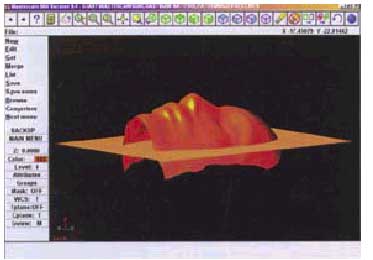

Filsinger saw in the MicroScribe/Rhino combination a perfect compliment to his graphics, animation, design, and advanced CAD/CAM courses. He uses them at Suncoast to digitize the image of an old mouse for toolpathing and machining copies with Mastercam. Touching grid points on the mouse; with the Micro-Scribe stylus, students loft an exact 3D model in Rhino, which converts the data to IGES. Easily imported into Mastercam, students now use the file to generate rough and finish multi-surface; toolpaths. Using pocket, multi-surface, and flowhne toolpaths, students create the grooves that separate the mouse buttons, then project the resultant toolpath onto the irregular surface of the mouse. Again, another complex project requiring the application of many drawing and toolpathing tech-niques, at a material cost of about 50¢. Throughout much of what Rick Filsinger has achieved over the past seven years with Suncoast’s highly select student body-- three of 10 applicants are admitted--flows the decades of experience of one community volunteer, Israel Levine, a retired engineer. He brings industrial standards to bear on students’ thought processes and working techniques. Since Filsinger isn’t an engineer, he and Levine engage in a lot of side conferencing. Levine received the "Community Volunteer" award from the state of Florida four years ago for his dedication to Suncoast’s mission. His one-on-one coaching--his gift of patient wisdom--has changed young lives beyond measure. His collaboration on three-dimensional analysis, a sophisticated digitizing/machining project, with Filsinger and a group of advanced students exemplifies the creative freedom and personal contact that raises Suncoast students’ achievements far beyond the norm. |

Techno is celebrating over 25 years of CNC technology

expertise. Our Educational sector provides industrial quality products

at educational prices with a network of award-winning Educators. We can

provide CNC Curriculums, CNC Projects, Technical Information and

Packages for any educational classroom.

Techno is celebrating over 25 years of CNC technology

expertise. Our Educational sector provides industrial quality products

at educational prices with a network of award-winning Educators. We can

provide CNC Curriculums, CNC Projects, Technical Information and

Packages for any educational classroom. Richard Filsinger

teaches the core courses in three of six "attractor

magnet" curricula in the Interdisciplinary Program at Suncoast

Community High School: Drafting Technology, Engineering Technology,

and Communication Technology. Filsinger concentrates on the end

products of

Richard Filsinger

teaches the core courses in three of six "attractor

magnet" curricula in the Interdisciplinary Program at Suncoast

Community High School: Drafting Technology, Engineering Technology,

and Communication Technology. Filsinger concentrates on the end

products of  Another

project-cost: 25¢ to 50¢ per student transforms random blocks of

acrylic scrap into stylish business card holders. This project

teaches students how to work using levels, how to make different

geometry visible and invisible, and to generate a wide assortment of

surfaces and toolpaths.

Another

project-cost: 25¢ to 50¢ per student transforms random blocks of

acrylic scrap into stylish business card holders. This project

teaches students how to work using levels, how to make different

geometry visible and invisible, and to generate a wide assortment of

surfaces and toolpaths.